Category: Screen Printing Equipment & Supplies

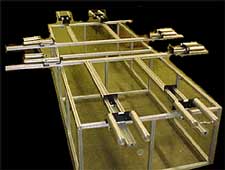

| A.W.T. World Trade, Inc. | | Company: A.W.T. World Trade, Inc. Click to view Company WebSite | | Providing screen printers with one complete manufacturing source for high-quality new and remanufactured screen printing equipment, parts and supplies, A.W.T. offers an array of screen printing equipment that is loaded with high-performance features most other screen printing equipment manufacturers offer only as options.

Designed for maximum productivity and engineered for years of reliable screen printing performance, A.W.T.'s complete line of screen printing equipment, parts and supplies provide the ultimate in screen printing convenience and the highest standards of screen printing quality.

Other divisions of The A.W.T. World Trade Group include Graphic Parts International Inc., an industry leader in the screen printing industry providing thousands of top-quality screen printing equipment replacement parts, supplies and remanufacturing services to the worldwide screen printing industry; and American M&M, manufacturer of such well-known and respected screen printing equipment as the Cameo, Hercules, Centurian and Daytona screen printing presses.

In addition to a worldwide network of screen printing equipment distributors and dealers, The A.W.T. World Trade Group has its headquarters in Chicago and a sales office in Oshkosh, WI; and screen printing equipment sales and distribution centers in Miami (serving the Central and South American markets) and Almere, Holland (serving the European market).

With more than 100 years of experience in the screen printing equipment, parts and supplies industry, A.W.T. World Trade, Inc.'s experienced technical support team and worldwide screen printing equipment sales force can quickly and confidently help you choose the right screen printing system for your individual needs. |

(Click Image for Larger View) |

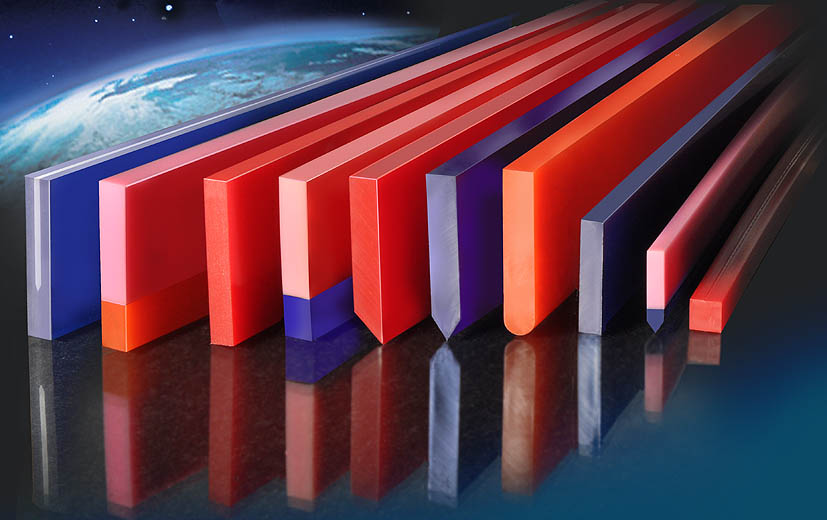

| Apolan High Performance Polyurethane Squeegee Blades | | Company: Apolan International Click to view Company WebSite | | Polyurethane Screen Printing Squeegees

were developed and improved over many years in

actual printing environment, utilizing the most

important principals of polymer chemistry. |

(Click Image for Larger View) |

| C32 Solvent-based screen ink | | Company: Sun Chemical Click to view Company WebSite | | A solvent-based ink series designed for hi-tech printing applications on polycarbonate, top-coated polyester and acrylic substrates. C32 inks are available in high-opacity blacks and whites, along with a range of transparent and high-opacity blending colors for efficiency. |

(Click Image for Larger View) |

| C37 Solvent-based screen ink | | Company: Sun Chemical Click to view Company WebSite | | An extremely flexible, solvent-based screen ink ideal for applications that require flexibility and high elongation. C37 Flexiform inks are formulated for decorating vacuum-formable plastics, such as those used for sports helmets. |

(Click Image for Larger View) |

| CD3 Colors | | Company: Sun Chemical Click to view Company WebSite | | A UV-curable ink series designed for the screen-printing decoration of all optical disc formats. CD3 Colors are designed with fast cure speeds and thixotropy engineered to minimize screen drip through and deliver excellent print definition. This ink series is supported by color matching services and ink room management tools to ensure efficient color reproductions. |

(Click Image for Larger View) |

| CDO Offset Inks | | Company: Sun Chemical Click to view Company WebSite | | 4-color process UV-curable offset inks used in the decoration of CD and DVD media. There are three different series of CDO offset inks, each engineered for specific offset equipment such as high-speed waterless and other dry offset presses. CDO products pass industry-standard environmental testing for CD and DVD manufacturing. |

(Click Image for Larger View) |

| COMETAL UV screen ink | | Company: Sun Chemical Click to view Company WebSite | | A UV-curable ink system developed for excellent exterior durability, flexibility, chemical and abrasion resistance properties on coated metal substrates. COMETAL is specially formulated for use on most polyester and vinyl-coated metal substrates and is an ideal alternative to conventional metal decorating inks. |

(Click Image for Larger View) |

| CX Series Solvent-based screen ink | | Company: Sun Chemical Click to view Company WebSite | | A conventional solvent-based screen-printing ink range for use on high-tech graphics, fascias and appliqués. CX Series is commonly used in the automotive industry. |

(Click Image for Larger View) |

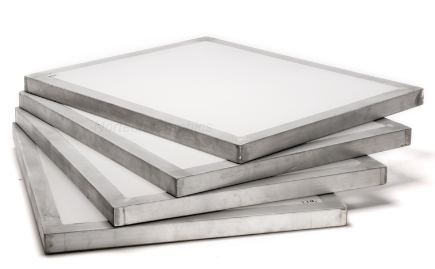

| DMA Exposure Unit | | Company: The Douthitt Company Click to view Company WebSite | |

Complete Metal Halide Printing Lamp Assembly.

Douthitt Heavy Duty Model MAGIC 83 Combination Light Integrator and Digital Timer complete with 10 memories.

No limit to height of screen because of special DOUTHITT “DEEP DRAW†BLACK Blanket. Under vacuum, this blanket swiftly molds itself to the shape of the screen frame and holds your positive in perfect contact.

Heavy Duty Vacuum Pump and Motor.

Vacuum Relief Bleeder Valve.

Loads Glass Down.

Effortless raising and lowering of the blanket frame.

All Heavy Gauge Welded Construction.

Bottom and Back are left open to facilitate cooling.

|

(Click Image for Larger View) |

| DMH Exposure Unit | | Company: The Douthitt Company Click to view Company WebSite | |

Complete 5000 Watt Metal Halide Printing Lamp Assembly.

Glass down design. Simply load, close, expose.

No limit to height of screen because of special Douthitt “Deep Draw†Black Blanket. Under vacuum, this blanket swiftly molds itself to the shape of the screen frame and holds your positive in perfect contact.

Douthitt Heavy Duty Model Magic 83 - 10 memory combination light integrator and digital timer.

Completely automatic operation. Vacuum delay and light exposure activated by closing the frame.

Cooling fans to insure against excessive heat build-up.

Heavy duty pump and motor.

Instrument panel conveniently mounted on side of unit.

All heavy gauge metal construction.

Large convenient access door on left side of unit.

OPTIONAL ACCESSORIES:

(A) Douthitt Heavy Duty Model 26 Silent Air Pumps instead of standard pump and motor (this pump requires compressed air). For Details.

(B) 8000 Watt Metal Halide Printing Lamp assembly instead of standard lamp.

|

(Click Image for Larger View) |

| DMUâ„¢ Ultrabond | | Company: Sun Chemical Click to view Company WebSite | | A patented UV-curable ink series developed for 1st and 2nd surface decoration of polycarbonate and other plastic films used for in-mold decoration. DecoMold Ultrabond DMU inks are designed to print on films that will undergo subsequent in-mold decoration processing used in the manufacture of automotive, telecommunication and appliance display parts. |

(Click Image for Larger View) |

| DMX Exposure Unit | | Company: The Douthitt Company Click to view Company WebSite | |

Complete 5000 Watt Metal Halide Printing Lamp Assembly.

Glass down design. Simply load, close, expose.

No limit to height of screen because of special Douthitt “Deep Draw†Black Blanket. Under vacuum, this blanket swiftly molds itself to the shape of the screen frame and holds your positive in perfect contact.

Douthitt Heavy Duty Model Magic 83 - 10 memory combination light integrator and digital timer.

Completely automatic operation. Vacuum delay and light exposure activated by closing the frame.

Cooling fans to insure against excessive heat build-up.

Heavy duty pump and motor.

Instrument panel conveniently mounted on side of unit.

All heavy gauge metal construction.

Large convenient access door on left side of unit.

OPTIONAL ACCESSORIES:

(A) Douthitt Heavy Duty Model 26 Silent Air Pumps instead of standard pump and motor (this pump requires compressed air). For Details.

(B) 8000 Watt Metal Halide Printing Lamp assembly instead of standard lamp. |

(Click Image for Larger View) |

| DMZ Exposure Unit | | Company: The Douthitt Company Click to view Company WebSite | | MODEL DMA Safe - No exposed printing rays! Flexible - No limit on depth of screen! Simple to Operate - Load - Close - Expose. Price Includes:

Complete 2300 Watt Metal Halide Printing Lamp Assembly. Shorter exposures, pollution free and longer bulb life with no fall off! This lamp is the ideal light source for screen type emulsions.

Exclusive glass down design. Simply load, close and expose.

No limit to height of screen because of special DOUTHITT "DEEP DRAW" BLACK Blanket. Under vacuum this blanket swiftly molds itself to the shape of the screen frame and holds your positive in perfect contact. The Blanket is secured to structural steel tubing and the blanket frame is raised and lowered by exclusive sliding toggle.

Heavy Duty Vacuum Pump and Motor.

Cooling fans to insure against excessive heat build up.

Heavy Optic clear A-1 Select Glass anchored to structural steel tubing to withstand pressure of the heaviest screen frame under vacuum.

Heavy Duty Digital Automatic Reset Timer.

Built in safety features:

The shutter on the lamp cannot be opened when the blanket frame is in a raised position.

When the front access door is opened all power is cut off.

Instrument panel conveniently mounted on side of unit with the following:

Vacuum Switch

Vacuum Gauge

Digital Timer

Bleeder Valve

All Heavy Gauge Metal Construction.

Unit finished in easy to clean, long wearing Epoxy Enamel.

Vacuum automatically cancels after exposure.

OPTIONAL ACCESSORIES:

5000 Watt Metal Halide Printing Lamp Assembly instead of standard lamp.

Douthitt Heavy Duty Model 26 Silent Air Pump instead of standard pump & motor (this pump requires compressed air).For Details.

Douthitt Heavy Duty Model MAGIC 83 Combination Light Integrator and Digital Timer in lieu of Timer. Integrator comes complete with vacuum time delay for one button automation.For Details.

|

(Click Image for Larger View) |

| DMZ-T Exposure Unit | | Company: The Douthitt Company Click to view Company WebSite | |

Complete 2300 Watt Metal Halide Printing Lamp Assembly.

Glass down design. Simply load, close, expose.

No limit to height of screen because of special Douthitt “Deep Draw†Black Blanket. Under vacuum, this blanket swiftly molds itself to the shape of the screen frame and holds your positive in perfect contact.

Douthitt Heavy Duty Model Magic 83 - 10 memory combination light integrator and digital timer.

Completely automatic operation. Vacuum delay and light exposure activated by closing the frame.

Cooling fans to insure against excessive heat build-up.

Heavy duty pump and motor.

Instrument panel conveniently mounted on side of unit.

All heavy gauge metal construction.

Large convenient access door on left side of unit.

OPTIONAL ACCESSORIES:

(A) Douthitt Heavy Duty Model 26 Silent Air Pumps instead of standard pump and motor (this pump requires compressed air). For Details.

(B) 5000 Watt Metal Halide Printing Lamp assembly instead of standard lamp. |

(Click Image for Larger View) |

| DSC UV screen ink | | Company: Sun Chemical Click to view Company WebSite | | A UV-curable, screen-printable overprint clear ink that delivers high gloss, excellent abrasion resistance and enhanced lightfastness when used on digital inks. DSC clear inks are designed for use over HP Indigo digital inks. |

(Click Image for Larger View) |

| DVD Whites | | Company: Sun Chemical Click to view Company WebSite | | A series of UV-curing screen inks specifically formulated for the decoration of optical discs. DVD Whites consists of DVD-S102 and DVD-2K7 gloss whites, both designed to deliver a smooth base to overprint with our screen or offset colors. DVD Whites exhibit minimal shrinkage during cure to provide distortion-free application. In addition, these inks pass industry-standard environmental testing for CD and DVD manufacturing. DVD-2K7 also meets the test specifications for Blu-Ray applications. |

(Click Image for Larger View) |

| Emulsion | | Company: Murakami Screen USA, Inc. | | Emulsion for graphics and textiles |

| Frames and stretching | | Company: SE-Technologies Click to view Company WebSite | | Aluminium frames in any size and design. Stretch and re-stretch of mesh. |

(Click Image for Larger View) |

| Graphic Screen Printing Presses | | Company: Thieme Corporation | | clam shell, 4-post and fully automatic printing presses. |

| HGâ„¢ solvent-based screen ink | | Company: Sun Chemical Click to view Company WebSite | | A solvent-based ink series known for fast-drying speeds and high gloss on a wide range of plastics. HG inks are suitable on thermoplastics, especially acrylics, rigid and plasticized PVC, CAB, various types of polystyrene, and polycarbonate. HG inks are an excellent choice for hi-tech graphics. |

(Click Image for Larger View) |

| Monocure MPC UV screen ink | | Company: Sun Chemical Click to view Company WebSite | | UV-curing screen inks specifically formulated for use on multiple plastic container substrates. These include PE, PP and PET containers. |

(Click Image for Larger View) |

| MTG-FORM | | Company: Sun Chemical Click to view Company WebSite | | A system of UV hardcoats that imparts protection and resistance for parts that undergo forming operations. MTG-FORM includes three components (Matte, Texture and Gloss) which can be blended together in any ratio to produce a UV hardcoat that meets virtually any requirement for texture, gloss and finish. |

(Click Image for Larger View) |

| MTG-NF | | Company: Sun Chemical Click to view Company WebSite | | A system of UV hardcoats that are used as overprint varnishes to deliver superior protection and resistance properties to hi-tech and automotive parts. MTG-NF includes three components (Matte, Texture and Gloss) which can be printed as stand-alone UV hardcoats or blended together in any ratio to produce a UV hardcoat that meets virtually any requirement for texture, gloss and finish. |

(Click Image for Larger View) |

| Murakami Thick Film | | Company: Murakami Screen USA, Inc. Click to view Company WebSite | | Murakami Thick Film

Ideal for printing High Density Inks

Produces sharp vertical emulsion side walls for easy high density printing.

Sharp emulsion shoulder cuts high density inks leaving a well defined vertical ink deposit.

Excellent resolution and stencil durability.

Obtain quality high density prints quickly. |

(Click Image for Larger View) |

| PDâ„¢ Panel Display Inks | | Company: Sun Chemical Click to view Company WebSite | | A UV-curing ink system that boasts excellent adhesive delamination resistance and flexibility, which is ideal for graphic overlays. PD Panel Display inks are formulated for printing on polycarbonate and top-coated polyester used in the manufacture of panel displays, membrane switch overlays and nameplates. |

(Click Image for Larger View) |

| Photocure PRO | | Company: Murakami Screen USA, Inc. Click to view Company WebSite | | Photocure PRO

Murakami’s newest emulsion. Dries very fast, is humidity resistant and exhibits a low surface tack for graphic printing. Excellent for large format graphic and industrial printing. Extremely high resolution properties. Can also be used for fine detail or halftone textile printing. |

(Click Image for Larger View) |

| Photocure SR | | Company: Murakami Screen USA, Inc. Click to view Company WebSite | | Photocure SR

All purpose emulsion for graphics, textile, and compact disc printing. Excellent for use with UV, solvent-based, and plastisol ink systems. Fast exposing, often 3-5x faster than diazo based emulsions. Virtually pin hole and fish eye free. Extremely durable on press.

|

(Click Image for Larger View) |

| Polyurethane Screen Printing Squeegees | | Company: Apolan International | | Squeegees were developed and improved over many years in actual printing environment, utilizing the most important principles of polymer chemistry.

The three major requirements, abrasion resistance, solvent resistance and flex fatigue place contradicting requirements on the polymermatrix. |

| PTFE Replacement belting | | Company: Taconic Click to view Company WebSite | | Taconic manufactures each of its TFE-GLASS™ and SRC-GLASS™ belts to custom specifications, depending on each customer’s individual needs. To help determine the best belt for your unique application, an experienced customer service representative is always on hand to discuss your requirements.

Choosing the Right Material

There are a number of factors to keep in mind when choosing the belting material for your application:

Temperature Range – Both our TFE and SRC-GLASS™ fabrics have the capabilities of withstanding -100°F - +500°F constant operating temperatures.

Pliability – If the material is to track around pulleys that drive the belt, the diameter of the pulley is critical. The smaller the roller the more flexible the belt must be. Taconic’s thinner materials (0.010†and under) are more pliant that the heavier coated fabrics.

Release Qualities – The surface finishes of our materials range from a rough, semi-porous finish to a super smooth surface. The release or fabric impression results desired will be a determining factor.

Strength – Options to be considered are breaking, tensile and tear strength. How much of a load the belt carries, how fast it moves and how tightly it will be tensioned all must be considered. |

(Click Image for Larger View) |

| Radiometer | | Company: International Light, Inc. Click to view Company WebSite | | The ILT800-UV CureRight Profiling UVMeter

This UV tester is a packed with features, easy to use, and includes ISO17025 accredited calibration to assure accuracy. The ILT800-UV simplifies UV measurement by continuously sampling until UV light is detected, then automatically providing the irradiance in W/cm2, and dose in J/cm2 |

(Click Image for Larger View) |

| RhinoBond Toughened Frame Adhesives | | Company: Rhinotech, Inc. Click to view Company WebSite | | RhinoBond Toughened Frame Adhesive system requires no pre-mixing of solvents and offers tension holding capabilities of over 90 newtons. The wide range of viscosities available will bond to wood or aluminum frames. The RBT series is flexible, impact-toughened, and has great removal characteristics. |

(Click Image for Larger View) |

| RhinoTech Pnuematic Bar Systems | | Company: Rhinotech, Inc. Click to view Company WebSite | | RhinoStretch Pneumatic Bar Systems are designed to offer speed, flexibility and size-expansion features. Ultimate accuracy is achieved through use of an adjustable, sliding, locking bar system. This system enables the fabric tension to be stabilized on the entire frame. Separate regulators and gauges allow complete adjustment in all directions, maintaining repeatable uniform tension—screen after screen. Each stretcher is custom-built with high-quality materials, which assure years of superior service. |

(Click Image for Larger View) |

| Smartmesh | | Company: Murakami Screen USA, Inc. Click to view Company WebSite | | Smartmesh: Precision Mesh, Exceptional Print Qualities!

Maintains consistent mesh openings that aids in preventing spot moire

Warp and weft threads are balanced to stretch equally during the print process

Smartmesh reaches stable tension levels quickly and retains tension for the life of the mesh

Smartmesh has memory, it resists both the initial pull of the squeegee as well as forces during the print stroke to preserve registration from the first print to the last

On finer meshes, the thread surface is treated to help ink transfer to substrate instead of hanging up in the mesh, yeilding a better reproduction of artwork |

(Click Image for Larger View) |

| SMCâ„¢ | | Company: Sun Chemical Click to view Company WebSite | | A unique solvent-based, screen-printing ink formulated to produce a mirror finish. SMC special metallic chrome inks are designed for second-surface printing on polycarbonate and polyester substrates. |

(Click Image for Larger View) |

| Squeegee Cutter | | Company: Thieme Corporation | | The new THIEME TSC G2 squeegee cutter - highest precision for small formats

The advantages at a glance:

fast and clean, no grinding dust

improved print quality

long durability of the squeegee edge, higher production rate

versatile due to an adjustable cutting edge

single- and double-sided cutting angles (V-shaped)

attractively priced

The TSC G2 from THIEME has been specially developed for high quality graphic screen printing; for high tech industrial applications and the special squeegee angle requirements needed for textile printing.

The well proven THIEME Rotankife® wet-cutting process with it’s practical ease of operation, is responsible for the perfect squeegee edge and for optimum print quality in a single cutting operation.

The razor sharp, rotating blade removes a very thin strip of rubber (approx. 0.8 mm) thus, greatly reducing squeegee consumption. The high quality of the squeegee edge is guaranteed by a specially developed coolant, which evaporates without leaving and residue. |

(Click Image for Larger View) |

| Squeegees | | Company: Pleiger Plastics Company Click to view Company WebSite | | Pleiger Plastics Company has been an innovative and leading manufacturer of High Performance Plei-Tech® polyurethane screen printing squeegees since 1986 and is a member of the Screen Printing and Graphic Imaging Association International. Our Plei-Tech® compounds are custom formulated to achieve high solvent resistance and excellent abrasion resistance. This combination results in a squeegee blade that will better maintain its durometer when subjected to aggressive inks and solvents, show minimal swelling during the print run, and retain its sharp edge longer allowing for continued quality during the screen print run, thereby increasing productivity.

UV, Epoxy, Enamel, Vinyl and other solvent based ink systems are extremely aggressive to squeegee blades. Inferior quality squeegees tend to; decrease in durometer, swell, and become dull at an accelerated rate due to their inability to resist the harsh solvents and abrasion against the stencil. Plei-Tech® squeegees are recommended because of their chemical resistance and exceptional abrasion resistance when exposed to aggressive ink systems. Pleiger Plastics Company currently manufactures a Plei-Tech® 22 and Plei-Tech® 15 (Vulkollan®) polyurethane screen printing squeegee.

Our Plei-Tech® 22 is excellent for most screen printing applications and is color coded for easy durometer reference by the printer. Standard Durometers and Colors for Plei-Tech® 22 are:

55A, Green

60A, Orange

70A, Yellow

75A, Green

80A, Blue

85A, Red

90A, Natural

Plei-Tech® 22 exhibits very good solvent resistance and excellent abrasion resistance.

Our Plei-Tech® 15 (Vulkollan®) is manufactured for those aggressive screen printing applications that demand the superior performance of this premium product. Plei-Tech® 15 (Vulkollan®) is Amber which will darken with age and exposure to UV and fluorescent light. Standard Durometers for Plei-Tech® 15 are: 60A / 70A / 75A / 80A / 85A / 90A.

Plei-Tech® 15 exhibits excellent solvent and abrasion resistance.

Plei-Tech |

(Click Image for Larger View) |

| Squeegees | | Company: Cherokee Rubber Company | |

(Click Image for Larger View) |

| Thieme 1000 | | Company: Thieme Corporation | | Semi-automatic, flatbed, shuttle table printing machine for flexible and rigid substrates.

The THIEME 1000 is the only screen printing machine which requires no lifting movements of the frame:

The screen is absolutely steady and vibration-free, even when printing large sizes

Better print quality no lifting movement of frame

Faster print speed the screen remains securely in position

Increased repeatability no unnecessary air swirling created by screen movements

Greater flexibility with screen remaining "open" longer |

(Click Image for Larger View) |

| Thieme 500 | | Company: Thieme Corporation | | Semi-automatic, flatbed, clamshell screen printing machine used for many applications.

The THIEME 500 is the result of an idea to combine new technology with a traditional, space-saving concept.

Compact, space-saving design

Excellent working accessibility

Ease of operation

Quick semi-automatic printing

A shorter set-up time due to an easily-accessed screen-frame mounting system

Flexible operation by means of adjustable drives

A complete machine re-design to meet almost all demands in the flatbed screen printing industry. |

(Click Image for Larger View) |

| Two-Part Frame Adhesives | | Company: Rhinotech, Inc. Click to view Company WebSite | | RhinoMite Adhesive systems offers high tensile strength, impact and solvent resistance. Both dry in approximately 10 -15 minutes. Once mixed, they have a pot life of seven or more days. Each unit is shipped as a kit with catalyst. |

(Click Image for Larger View) |

| UV Process Supply | | Company: UV Process Supply, Inc. Click to view Company WebSite | | UV Process Supply, Inc. founded in 1979 with the goal to service the growing UV Curing market. At that time there were only companies producing UV coatings and Inks, and UV Curing equipment. The realization was that it took more than these two components to do a “processâ€. What else is needed to create a successful application? With that five product categories were created to address the problems associated with the physical properties of the process.

Safety Products was the first category, and hand cleaner was the first product. Most waterless hand cleaners are made with mineral sprits, and that solvent used with acrylates can lead to skin problems. We created a waterless hand cleaner that was oil based rather than solvent based. Next was our skin lotion, which contains aluminum hydroxide able to neutralize the acrylic acid based coatings. Gloves were all tested with the most popular monomers to insure that they would provide proper protection when used with clean up solvents. Thus we do not carry vinyl gloves as they do no not provide proper protection with UV Coatings and inks. Barrier creams were a natural requirement as they present additional protection especially around finger nails and under rings, where inks might collect unnoticed. In the area of eye protection, all products are rated based on the ability to filter UV light. Even our splash goggles filter UV as to always insure optimum protection.

Ink and Coating Handling is our second category and represents two features associated with the process. First is safety related; that if you can pump the coating, there is less physical contact with the material that can cause a problem. We learned to specify the proper pumps for UV Curing from customer experience. They learned that if they were using a piston pump, it would seize, when the friction of the piston would cause minute polymerization on the interior wall of the pump. So the pumps need to be either double diaphragm pumps or peristaltic. All wetted parts in the pump product line has |

(Click Image for Larger View) |

| WINâ„¢ | | Company: Sun Chemical Click to view Company WebSite | | A series of transparent, dye-based UV inks for printing panel display windows. WIN inks are specially formulated for printing onto polycarbonate. |

(Click Image for Larger View) |

| ZGL | | Company: Sun Chemical Click to view Company WebSite | | A conventional solvent-based two-pack catalytic screen-printing ink fitting for a range of glass applications, including containers, furniture, architectural and gaming machines. |

(Click Image for Larger View) |

|